Frequently Asked Questions

We've put together some commonly asked questions to give you more information about Viance treated wood products.

If you have a question you can't find the answer to, please contact us.

Many homeowners have questions about using treated wood for raised vegetable and garden beds. Here's what the scientists have to say.

We've put together some commonly asked questions to give you more information about Viance treated wood products.

If you have a question you can't find the answer to, please contact us.

The construction of an in-ground, raised vegetable garden should use materials designed to withstand ground-contact exposure. Treated wood labeled for ground contact can be used to build to build raised beds for edible garden plants. Above ground contact labeled wood, such as Ecolife®, is not intended or approved for ground-contact exposure. Preserve® CA pressure treated for ground-contact exposure, can be used around edible plants, and is available in 2x8's and wider as well as larger posts such as 4x4's or 6x6's which may work as the retaining wall or perimeter of a raised vegetable garden.

Pressure treated wood is the application of a preservative formulation that is forced into the wood under pressure in a large cylinder. AWPA treatments are a safe and proven means to preserve and protect outdoor wood from decay and termite attack. Pressure treatments extend the life of wood, and reduce the impacts on forests, making them truly one of the most sustainable building materials used in the world today.

Wood products for construction are typically treated in a factory, using a pressure process. The product is loaded into a cylinder, and then the cylinder is filled with a solution containing the preservative chemicals. The vessel is pressurized to force the solution into the wood. Most dimensional lumber, as well as plywood, can be treated this way.

Wood is an environmentally sound, economical building material that can be used either indoors or outdoors for a wide variety of structural and decorative applications. Unfortunately, untreated lumber cut from most commercially harvested tree species is subject to attack by insects or to decay caused by fungi and bacteria. The decay or insect hazard is greatest in exposures where the wood is subjected to moisture. Wood in outdoor exposures, either in ground-contact or in above-ground applications, is susceptible to attack. The potential for wood deterioration is greatest in hot and humid climates, which allow insects, fungi and bacteria to thrive. Destruction of untreated wood in aquatic environments can be caused by a variety of marine organisms. Wood should be treated with a preservative system to control the destructive activities of these organisms and ensure long-term structural soundness and serviceability.

Lumber that has been treated to AWPA above-ground retention levels (UC3B) is standardized to provide a level of performance that is appropriate for above-ground applications. Proven above-ground products that meet the AWPA standards have historically performed well without the excessive use, or potential costs, associated with increasing those preservative levels for high-decay/ground contact level treatments.

The green color you see on treated wood is caused by chemical reactions that take place between the preservative components and the wood. Copper is still the most widely used element in wood preservatives and creates a green color on the wood. As wood dries and reacts to sun’s ultraviolet rays, the green color will fade.

No. All treated wood is not the same.

Above ground treated lumber is code compliant for use in applications where the wood does not touch the ground (e.g. deck joists and support beams used as critical structural members, decking, railings, and above ground fence pickets), or when use is six inches or more from the ground.

Wood treated to ground contact levels is required for direct contact with the ground (e.g. fence posts, etc.), and in cases where a high-decay hazard is very likely to occur (e.g. soil/leaves/debris build-up or accumulations are left to remain in contact with the wood, poor ventilation, tropical climates, etc.).

Our preservative products Ecolife® and Preserve® CA are treated under the AWPA standards for above ground or ground contact retentions to provide proven wood protection.

Ecolife, with its built-in wood stabilizing system, has been specifically designed for above ground use, and as such has been proven to perform. Ecolife treated wood exhibits reduced cracking, warping and splitting in service, and uses no more chemicals than is absolutely necessary.

In this economy, everyone is looking for ways to save money and stay in business. The building products industry is no exception. With increased competition for sales and market share, lowering the quality of products or services is one way to save money. While a reduction in cost and quality might help some organizations survive on a short-term basis, it can have unintended long-term consequences. For this reason alone, it’s important to provide high-quality products and services to the public to maintain the trust of the customer to gain repeat business and positive referrals. AWPA has been the premier developer of consensus-based standards for treated wood products since 1904, which is why the building codes rely on AWPA Standards.

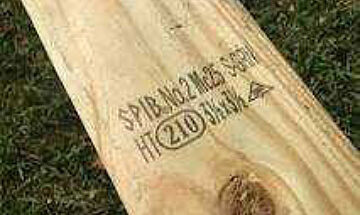

There are naturally-occurring fungi in the ground that attack lumber, so lumber destined to be used in the ground must be treated to a higher standard, or retention level, of fungi-resistant preservatives in the wood. The end tags on treated lumber will provide you with proper use designations. Look for Above Ground or Ground Contact on the end tag.

Retention levels refer to the amount of preservative retained in the wood following the treatment process. Retention levels can be different based on the wood preservative system used to pressure treat the wood product and its intended end use (ground contact, above ground contact, etc.). It is recommended to purchase treated wood products for the intended exposure condition. Typically, wood products are treated for “above ground use” and “ground contact use”. The treated wood end tag should state the recommended end use for the treated wood product.

The American Wood Protection Association (AWPA) standards provide a list of standardized preservative formulations in the US. The AWPA standards are recognized worldwide, as their American National Standards Institute (ANSI) accredited process thoroughly evaluates, reviews and standardizes preservatives. AWPA standardized preservatives are approved by all building codes for their intended uses. Visit AWPA.com and their Technical and References sections for Homeowners, Specifiers, Builders and Retailers for more information.

Yes. Viance’s residential preservatives are recognized and listed in the AWPA’s Book of Standards, which are referenced in the IBC and IRC building codes. Every preservative standardized by the AWPA is supported by rigorous laboratory and field test data that undergoes an extensive scientific peer review by industry-leading wood scientists, participating academics and independent industry experts/participants. To help ensure that AWPA-standardized products meet ongoing expectations, performance data is scrutinized every five years via the same peer review process to reaffirm its effectiveness.

In today's marketplace, there are many wood preservative systems available to the public. It is important that those wood preservatives reviewed by AWPA's Technical Committees and found in AWPA Standard U1 are selected at retentions that are appropriate for each Use Category, shown in the table below.

It is important to select wood that has the appropriate level of preservative for its intended use. The language changes to the AWPA Use Category System and supporting guideline tables are intended to help clarify the scenarios where a higher level of protection should be considered/used. Material that is treated with Viance’s preservatives for Above Ground use is code compliant (IBC and IRC) and warranted accordingly. For cases where the material may be in higher decay environments/scenarios, a higher level of preservative protection is required.

Look for a lumber end tag. Each piece of treated wood should have a tag containing information regarding the preservative used, the appropriate end use (Above Ground or Ground Contact) and the quality standard.

Ecolife® is standardized by the American Wood Protection Association (AWPA) and building code compliant (IRC and IBC). Ecolife-treated wood meets stringent industry standards and has the AWPA U1 and the CheckMark logo on the end tags as assurance that it has been quality-inspected by the American Lumber Standard Committee (ALSC) accredited third-party inspection agency.

Yes. The AWPA’s standards are directly referenced in the IBC and IRC building codes. The AWPA U1 standard will continue to allow above ground treated wood for use in critical deck joists and support beams, decking, railings, fence pickets, and many other outdoor project applications. Material treated and used for above ground construction with Viance’s preservative treatments will be covered under the terms of our Lifetime Limited Warranty, when used appropriately. This includes material used for above ground deck joists and support beams, which are critical to the performance and safety of an entire structure/project.

New language changes to the AWPA standards and supporting guideline tables can be somewhat confusing. These changes reference the use of (UC4A) retentions on treated wood components considered difficult to replace. Because the difficulty of replacement can be very subjective, standard deck joists and support beams treated to above ground retention levels (UC3B) remain code-compliant.

Products with increased chemical/retention amounts are needed for building components used in high-decay situations (e.g. within 6” of the finished grade and supported on permeable building materials, in tropical climates, when soil/leaves/debris are left to accumulate/remain and potentially replicate ground contact conditions, poor ventilation around decks, etc.).

No. Although all deck joists and support beams are critical to a structure, they all will not be required to be treated to ground contact retentions unless at least one of the following conditions occurs:

Yes. Because conditions for wood decay are optimal in most soils, material treated for ground contact use is required. Ideal deck building techniques may include the use of non-permeable building hardware (fixed or adjustable), which are used as a barrier between a concrete footer and structural support posts/beams to potentially improve the performance of the treated wood. Measures should be taken to ensure that the accumulations of soil/leaves/debris are minimized or prevented during the project planning and construction phase. To extend the performance of the deck materials and components, regular inspection and maintenance should be performed.

The AWPA is the only ANSI (American National Standards Institute)-accredited standards developer that requires a rigorous evaluation plus an open peer review of that data where the largest collection of wood chemical, wood technologists and wood preservers gather in North America for the express purpose of evaluating which wood preservatives are worthy to be standardized in the AWPA Book of Standards. If you are a homeowner, it probably means that you’re not content to simply ask for any kind of treated wood and that you want products that will provide years of service. You are likely searching the internet to find the product best suited to your needs, and you appreciate the value of wood treated to industry standards – standards developed by experts in the field of wood protection. Low-cost alternative preservative-treated wood is available, but you want products with proven performance. For more information visit the American Wood Protection Association (AWPA) web site.

There are several key bits of information you should see on the treated wood end tags: First, look for “AWPA U1” on the end tag. If you cannot find "AWPA U1" and the Use Category, the wood probably does not meet AWPA Standards. Another helpful tool to identify wood treated in accordance with AWPA Standard U1 is the “CheckMark” program developed by the Western Wood Preservers Institute. The CheckMark, combined with the logo of an ALSC (American Lumber Standard Committee) accredited agency, demonstrates conformance to AWPA Standard U1.

Besides the fact that most architects and engineers specify AWPA Standards for treated wood, AWPA Standards are the only wood treatment standards listed directly in the IBC and IRC. You could use some of the low-cost alternative preservatives, but there is no guarantee or requirement that the designer or local code official will approve it. In addition, AWPA has over 100 years of history in developing reliable treated wood standards. Our standards are developed in an open, consensus-based, ANSI accredited process to ensure a stringent review of performance data while providing due process for all participants. Most of the world’s experts in wood protection actively serve on AWPA Technical Committees – a level of expertise unmatched elsewhere.

The Use Categories are a shorthand method of describing the various hazards to which wood products may be exposed. A brief description of the Use Categories is shown, but if you would like additional details on the AWPA Use Category System, please download this excerpt from AWPA Standard U1.

Use Category | Brief Description |

UC1 | Interior Dry |

UC2 | Interior Damp |

UC3A | Exterior Above Ground, Coated with Rapid Water Runoff |

UC3B | Exterior Above Ground, Uncoated or Poor Water Runoff |

UC4A | Ground Contact, General Use |

UC4B | Ground Contact, Heavy Duty |

UC4C | Ground Contact, Extreme Duty |

UC5A | Marine Use, Northern Waters (Salt or Brackish Water) |

UC5B | Marine Use, Central Waters (Salt or Brackish Water) |

UC5C | Marine Use, Southern Waters (Salt or Brackish Water) |

UCFA | Interior Above Ground Fire Protection |

UCFB | Exterior Above Ground Fire Protection |

We have also developed an infographic that will assist you in determining the appropriate preserved wood for your particular project. You can download the Use Category infographic here.

Viance Residential Treated lumber products. Ecolife® and Preserve®, carry a Lifetime Limited Warranty against fungal decay and termite attack. We recommend annual cleaning and resealing to keep your project looking good.

Incising is the process of cutting numerous small slits into the surface of a piece of wood in order to increase the amount of preservative taken up by the wood during treatment. Some Western wood species are particularly hard to treat, and incising is necessary to meet the penetration requirements in treatment standards.

Pressure-treated wood may be used inside, and is commonly used for the sill plates of homes and FRTW; fire-retardant treatments like D-Blaze® offer additional protection from fire and smoke development.

Properly dispose of all sawdust and construction debris after all projects. Many treated wood products do not emit any vapors and are safe for interior use. Check use information on specific products. Treated wood should never be used for countertops or where it may become a component of food. In fact, the Food and Drug Administration does not recommend using any wood for kitchen counter-tops or food-cutting boards because knife cuts may allow food particles to become entrapped, creating an unsanitary environment.

Treated wood is required by building codes in numerous applications. Exterior wood treatment solutions extend the natural life of the wood used in construction applications and provide exceptional performance for outdoor projects. Treated wood may be specified for interior framing where termite attack is prevalent, or where fire retardant materials are needed.

All product and technical information pertinent to the Viance chemicals is available for download on the Product Information page. The wood and lumber products that are treated with Viance products come from various sawmills and wood treaters, so additional information on the lumber products must come from the actual lumber suppliers of the materials used in the project.

Product contribution points and building certifications for LEED and the National Green Building Standard (plus their web links) can be found on this compiled document that can be helpful indicating possible points from Viance preservative products.

Sustainable forestry programs such as FSC or SFI are managed entirely by the companies that procure and resell wood through their distribution networks. Viance develops and manufactures only the preservatives/treatments used. All FSC/SFI information would be provided by lumber suppliers.

All product and technical information pertinent to the Viance preseratives /fire retardant treatments used to treat wood is available for download on the Product Information page.

Most of the weight added to treated wood comes from water used to carry the preservative components. A freshly treated piece of lumber may contain as much as 2-4 gallons of water per cubic foot or about 16-32 lbs. per cubic foot. As the wood dries and the water evaporates, only the preservative will remain.

Kiln drying after pressure treatment (KDAT) removes a large amount of the moisture from the wood. Most treated lumber products today are air dried. Kiln drying after treatment (KDAT), will add cost to the process and the finished products; however, KDAT wood tends to reduce warping, as it is a more controlled drying method.

Viance wood preservative products do not contain formaldehyde. However, the glues used in the production of plywood, laminates or other engineered wood products may contain formaldehyde. Contact the engineered wood producer for information regarding the use of formaldehyde in their products.

We recommend a semi-transparent, oil-based penetrating finish stain.

For exterior project applications, treat all field-cut ends of boards and drilled holes with a brush-on wood preservative. Copper naphthenate formulations are available from home centers, lumber dealers and hardware stores. Deck stains and sealers do not provide adequate protection.

Do you have questions about using pressure-treated lumber for your deck? If so, click on each of the Deck Installation FAQs below.

In most cases, a light sanding will remove or lighten the grade stamp.

Treated wood is often still damp when delivered, so it is recommended to butt deck boards tightly together during installation as they will shrink slightly in width and length as they dry out. This will create acceptable gaps between the boards for water to drain off the surface. How much a board will shrink will be dependent on how much moisture remains in the wood after it was installed.

If the wood is allowed to dry prior to installation, a small gap should be left between boards.

Ultimately, your deck boards should have an edge gap between ¼ inch and ⅜ inch to allow for proper ventilation, draining and for debris to pass through. Wet or dry, boards should be installed tight end-to-end.

Install screws no closer than 1/2" from board ends and sides to prevent splitting.

Always use the best-looking side of a deck board for the deck surface. Fasten thinner boards to thicker boards.

For field-cut ends and drilled holes in treated lumber, use a brush-on wood preservative. Copper naphthenate formulations are available from home centers, lumber dealers and hardware stores. Deck stains and sealers do not provide adequate protection.

You can use nails or screws when you build your deck. However, screws are more secure and don’t pop out of the wood like nails do, making them the superior option for securing the deck and for safety. Nails that pop out of the deck can become a nuisance, not to mention they can injure your feet or those of your loved ones. Additionally, nails don’t fasten the deck as securely or for as long a period of time as screws do.

Viance always recommends that current building codes be consulted for up-to-date lists of approved fasteners. Hot-dipped galvanized and stainless-steel fasteners are recommended for use with preservative treated wood. There are also several new-coated fastener systems available.

Hot-dipped galvanizing is a process of coating zinc over bare steel to provide a protective layer. The bare steel is cleaned, pickled, fluxed and then dipped in a molten bath of zinc and allowed to cool prior to inspection and shipping.

If you remember your high school chemistry, copper is conductive. That means copper preservative formulations for treated lumber have a corrosive effect on most metals — like the nails and screws that are used to hold boards together.

MCA (micronized copper azole) and CA (copper azole) are in common usage today. In fact, the majority of treated lumber on the market contains copper. Because stainless steel and hot-dipped galvanized fasteners are not reactive with copper, they are the only logical choice to make when it comes to fasteners for your decking or for anything that is made with copper preservative treated lumber.

To be compatible with copper preservative treated lumber, galvanized fasteners must be “Hot Dipped Galvanized” and display the code “G-185” (which refers to the thickness of the galvanization). Different brands have different designations for this—such as “ZMAX” or “Triple Zinc”—but the brand names will vary by region. It is safest to confirm that the “G-185” code is also present.

Stainless steel fasteners can also be used because good grades of stainless steel are considered virtually corrosion-proof, and in some locations (around salt water, for instance), these are the preferred fasteners.

Copper fasteners are also immune to corrosion by a copper formula but are not a very practical alternative to use in building a home.

Avoid the fasteners that are labeled “electro-galvanized,” or are marked “G-90” or “G-60”. They were designed to be compatible with the old CCA preservative, and won’t hold up to the new copper treated wood.

Setting the posts in concrete does not affect the warranty in any way. We recommend that you follow your local building codes and proper drainage requirements when setting posts for decks.

Check out Deck Finishing FAQs below.

Pressure treatment with waterborne preservatives does leave some moisture in the wood that may affect the penetration and drying of stains and paints. Ecolife treated wood can be stained or painted. Ecolife also contains a water repellent so you don’t have to apply a sealant for up to three years after installation.

For optimal performance of paint and stain coatings, allow the treated wood to dry prior to application. To ensure the wood is dry for staining, painting or sealing, test the wood with a few drops of water to see if the wood is dry enough to readily absorb water. As soon as the wood is porous enough to accept the stain, paint or sealant, it is ready for application. Typically, treated wood will dry and be ready for finishing 60 days after installation. However, estimating exactly how long treated lumber will take to dry is hard to predict and will depend on the time elapsed since pressure treatment, sun exposure, local temperature and recent weather conditions.

We recommend a good quality oil-based or water-based stain or exterior wood water sealant product. Always follow the manufacturer’s application and use instructions.

Semi-transparent stains are best for color. Paint or solid-color stains will show wear on frequently used pathways, such as on stairs or entryways. Follow the manufacturer’s instructions and the advice of your local paint dealer for best results.

Most water repellent coating manufacturers recommend an annual application. Follow the manufacturer’s instructions.

Keep your deck looking good. Below we have a list of Deck Maintenance FAQs to help you with your maintenance questions.

We recommend that the use of a pressure washer be limited to only the highly-experienced and/or professionals. Improper use can damage the wood surface and fibers. If you choose to use a power washer, use the lowest possible pressure setting (keep it under 500 psi) and fan tip only approximately 18 inches from the deck.

Mold that you find on pressure treated wood is not an indication of a fungal attack. Mold can grow on the surface of many products including wood (treated and untreated) due to exposure to moisture. To remove mold from your treated deck, use mild soap and water solution and a stiff brush.

Mold Growth

Mold and mildew are present everywhere in our environment, both indoors and outdoors. Mold and mildew need four things to thrive: air, water, temperatures between 32 and 120°F, and a food source, conditions that are common wherever humans live, work, and play.

The best way to minimize mold and mildew growth is to control water and food sources. When it comes to mold or mildew on wood decking, water and organic matter are the primary conditions that enable mold and mildew colonies to thrive. To minimize these conditions, make sure water has the ability to flow away from the deck surface and areas surrounding the deck to lessen the absorption of water. Ensure there is adequate ventilation between deck boards and underneath the deck surface, so water can rapidly evaporate.

And since both mold and mildew feed on dead or decaying organic matter, so it is important to keep your deck clean of leaves and debris.

Cleaning Your Deck

To minimize mold on your decking, clean your deck as often as needed, at least twice each year. Climate conditions vary in different regions of the country and may necessitate more periodic cleaning.

Remove leaves, debris, and other organic materials that provide a food source for mold.

If mold is present, there are many commercial products available for cleaning mold. We recommend commercial cleaners containing oxalic acid. For best results, follow the manufacturer’s instructions and use cleaners within their stated shelf life. Do not mix recommended cleaning products together as harmful chemical reactions could occur. To maximize application coverage, remove excessive organic growth or clumps prior to applying the cleaner.

Coatings for High Mold-Prone Environments

For environments prone to high mold growth, there are commercially available coatings and finishes that seal the wood surface when applied and they should be maintained per the manufacturer’s instructions.

Tips for Minimizing Mold

D-Blaze® is a specialized application to make wood fire retardant. To find out more about it, click on any of the D-Blaze® FAQs to get answers to your questions.

All product and technical information pertinent to the Viance chemicals is available for download on the Product Information page. The chemicals in D-Blaze are free of VOCs and formaldehyde, and Viance provides a letter affirming that fact on the same page. The wood and lumber products that are treated with D-Blaze come from various sawmills and wood treaters, so additional information on the lumber products must come from the actual lumber suppliers of the materials used in the project.

All product and technical information pertinent to the Viance chemicals used to treat wood is available for download on the Product Information page. Sustainable forestry programs such as FSC or SFI are managed entirely by the companies that procure and resell wood through their distribution networks. All FSC/SFI information would be provided by these lumber suppliers.

D-Blaze fire retardant treated wood (FRTW) is designed for above ground use that is 100% sheltered from precipitation and direct wetting. D-Blaze FRTW is suitable for applications where fire retardant construction materials are specified or required by building codes.

ICC ES - ESR-2645 for D-Blaze FRTW applies, and D-Blaze also meets the American Wood Protection Association (AWPA) standards P50, U1, UFCA for interior Type A (HT) use. Three-part editable specifications are available here and at www.ARCAT.com.

No. We do not recommend this because it could compromise the performance of the D-Blaze in terms of flame spread rating and smoke generation should a fire occur.

The D-Blaze 50-year warranty covers structural failure caused by a reduction in strength below the recommended design application values of D-Blaze treated wood products due to exposure to roof temperatures of 150° F (lumber) and 170° F (plywood).

No. D-Blaze does not contain urea or formaldehyde as an active ingredient or inert component.

No. D-Blaze does not contain any volatile organic compounds.

D-Blaze FRTW should be kept dry during transit, storage and while on the job site. If D-Blaze gets wet, then the performance properties of the treatment may suffer. Since the degree of rain exposure would vary in every case, if D-Blaze gets wet during transit, storage or on the job site, then the D-Blaze FRTW must always be dried to original specifications before being covered or enclosed.

National and local building codes change frequently. Viance recommends that local building codes always be consulted for lists of currently approved fasteners and fastener systems. Currently, hot-dipped galvanized steel or stainless steel fasteners are recommended.

Yes. D-Blaze® FRTW has been tested by independent laboratories following industry standards ASTM 5516 & ASTM 5664 to develop strength reduction factors for various use conditions, including roof temperatures of up to 150° F for lumber and 170° F for plywood. Specifiers, architects and designers should consult and adhere to the Strength Design Adjust Factors and Span Ratings published in the current D-Blaze product literature.

Yes. D-Blaze is approved by national and local building authorities. Consult current D-Blaze product literature and ICC ESR-2645 for the latest details.

Visit the D-Blaze product page for the latest list of testing and approvals.

Cutting to length, drilling, and diagonal cuts, as well as light sanding, are permitted. Exposed areas are not required to be field coated. Ripping dimensional lumber is not allowed.

There are some differences between lumber treated with Ecolife® and that treated with Preserve®. You can find some answers about the differences by clicking on any of the Ecolife vs. Preserve FAQs.

In most cases a light sanding will remove the grade stamp or lighten its appearance.

Lowe's carries Ecolife (EL2) in narrow widths and deck boards - Check the end tag for the EL2 designation.

Ecolife® / Severe Weather® and Preserve® are both preservative treatments that can be used for above ground applications of treated wood, such as decking or fencing. Both products are standardized by the American Wood Protection Association (AWPA), indicating that they have demonstrated proven performance. Ecolife / Severe Weather is a non-metallic preservative with a built-in wood stabilizer which helps the treated lumber look better for longer. The built-in stabilizer helps reduce the amount of cracking, checking and splitting that occurs in wood exposed to the elements.

Ecolife/Severe Weather (with Ecolife) is approved for use in applications six inches or higher from the ground-- above ground use. At Lowe's, Ecolife is designated with "EL2" on the end tag and is available in heights and widths up to 2x6, railing components, fence pickets and panels.

DCOI, the active ingredient in Ecolife, won the EPA President's Green Chemistry Challenge Award in 1996 for replacing TBTO as an antifoulant in the hulls of ocean-going vessels. DCOI offers an environmentally advanced option and is also used in the preservative treatment of UltraPole NXT® utility poles and crossarms.

Preserve CA can be used in either above ground or ground contact applications depending on retention levels of the preservative treatment. Check the end tag for the appropriate use.

The construction of an in-ground, raised vegetable garden should use materials designed to withstand ground-contact exposure. So while the preservatives are safe for use near edible garden plants, Ecolife® is not intended or approved for ground-contact exposure. Preserve can be pressure treated for ground-contact exposure, is equally safe around edible plants, and is available in larger posts such as 4x4's or 6x6's which may work as the retaining wall or perimeter of a raised vegetable garden. Read more here on current research on treated wood use in garden beds.

Preserve is a copper-based preservative and it is the copper in the preservative which imparts the green color. Ecolife / Severe Weather is not a copper-based preservative although there is some colorant added to distinguish the Ecolife® treated wood from untreated wood. The colorant in Ecolife does not impart a strong green tint on wood after treatment.

It is very important to use proper safety procedures when installing pressure-treated lumber. For some helpful guidelines, please click on the Safety Practices FAQs below.

Wear gloves when handling treated wood as wood may splinter, and always wear eye protection and a dust mask when cutting, sawing or sanding treated wood to reduce inhalation and prevent irritation to the nose, eyes and skin.

All treated wood scraps, debris and sawdust should be cleaned up and disposed of after construction in accordance with federal, state and local regulations.

When treated wood is burned, the chemical components of the preservative are concentrated and can be released into the ash and in particulates in the smoke. Some of these components can be harmful to the environment. Federal and state regulations mandate that treated wood be disposed of properly.

Picnic tables are used primarily for serving pre-prepared food, while a kitchen countertop is used to prepare food and used as a cutting surface for raw food. Raw food can absorb the preservatives and be ingested.